Dry Ice Clean Blast

Dry ice blasting is a new method of cleaning heavy machinery, equipment and even entire facilities, which employs the use of dry ice in the form of either minute-sized pellets or thin shavings as the cleaning medium. Snow-Pack can provide cleaning services for you or supply you with the dry ice blasting equipment.

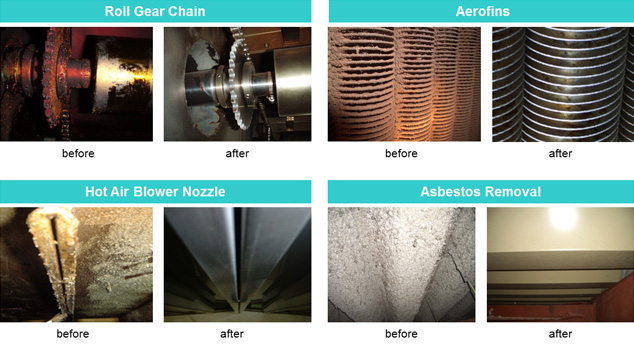

Actual applications of Dry Ice Clean Blast

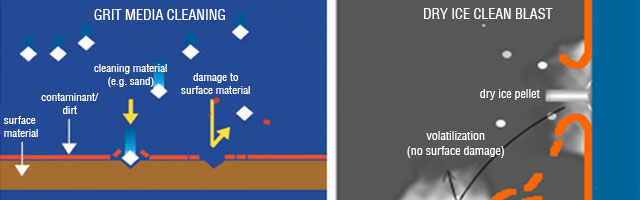

Most modern, conventional cleaning methods typically use solid or liquid cleaning products, usually ejected at very high speeds unto a set surface, the friction of which facilitates cleaning. In spite of its relative reliability, such methods of cleaning (i. e. sandblasting, sodablasting, water-jet cleaning) usually do more harm than good in that they tend to eventually exacerbate the general wear and tear associated with heavy machinery, thus eliciting more expenses when it comes to maintenance and repairs.

Comparison of Traditional Grit Media Cleaning vs. Dry Ice Clean Blast

The cleaning principle of dry ice blasting is the gas wedge effect. When dry ice strikes the basal surface of the contaminant, volatile energy causes CO2 to be released laterally to lift up and strip away the contaminants. Dry ice is accelerated to supersonic speed causing miniature explosions on the surface and stripping away unnecessary material from the base layer. The cleaning surface remains undamaged unlike the abrasive grit media cleaning.

A Comparison of Dry Ice Clean Blast with Other Industrial Methods

| Industrial Method | Secondary Waste | Conductivity | Abrasives | Toxicity | Effectiveness |

| Dry Ice Clean Blast |

None | None | None | None | Superior |

| Water blast (Cleaning) | Present | Present | None | – | Limited |

| Sand blast (Abrasive) | Present | None | Present | – | Limited |

| Soda blast (Abrasive) | Present | None | Present | – | Limited |

| Solvent/Chemical (Stripping) | Present | N/A | None | Present | Limited |

| Power tools (Shaving) | None | N/A | None | N/A | Limited |

| Manual tools (Shaving) | None | N/A | None | N/A | Limited |

Benefits of Dry Ice Blasting

- No Residues – Dry ice blasting does not emit secondary waste or contaminants. Processing waste is greatly reduced or eliminated.

- No Damage to Base Material – ensures longer life for your machinery as it does not add to the wear and tear, eliminates costly repairs/parts replacement.

- Safe – No toxic solvents or chemicals are used, making it a safe method with no adverse effects on worker’s health or the environment.

- Efficient and Convenient – No need to disassemble/reassemble items to be cleaned. No need to collect blast material. (reduced work time/cost).

| Applicable Industries | Applicable Equipment |

|---|---|

| Film | Vacuum Evaporation Eqpt |

| Coating | Driers |

| Lenses | Paint Coaters |

| Glass | Coating Machines |

| LCD | Incinerators |

| PCB | Applicators |

| PET Acrylic | Printing Eqpt |

| Semiconductors | Drying Furnaces |

| Vapor Deposition | Film Production Eqpt |

| Automobiles | Stretching Machines |

| Medical | Reflow Furnaces |

| Packaging | Automobiles |

| Food | Aircraft |

| Printing | Asbestos Removal |

| Construction | Dioxin Removal |

| Electrical | Toxin Decontamination |